GRP Grating — Top Benefits of Using GRP Grating for Industrial and Commercial Projects

Introduction

In today’s fast-paced industrial and commercial sectors, safety, durability, and cost-efficiency are essential factors when selecting materials for flooring, walkways, platforms, and structural support. GRP Grating has emerged as one of the most reliable and versatile solutions for modern projects. With its impressive mechanical properties, corrosion resistance, and long lifespan, it has become a preferred choice across industries such as marine, construction, chemical processing, wastewater treatment, and more.

This article explores the top benefits of GRP Grating, why it outperforms traditional materials like steel and wood, and how it can significantly enhance project performance and safety.

What Is GRP Grating?

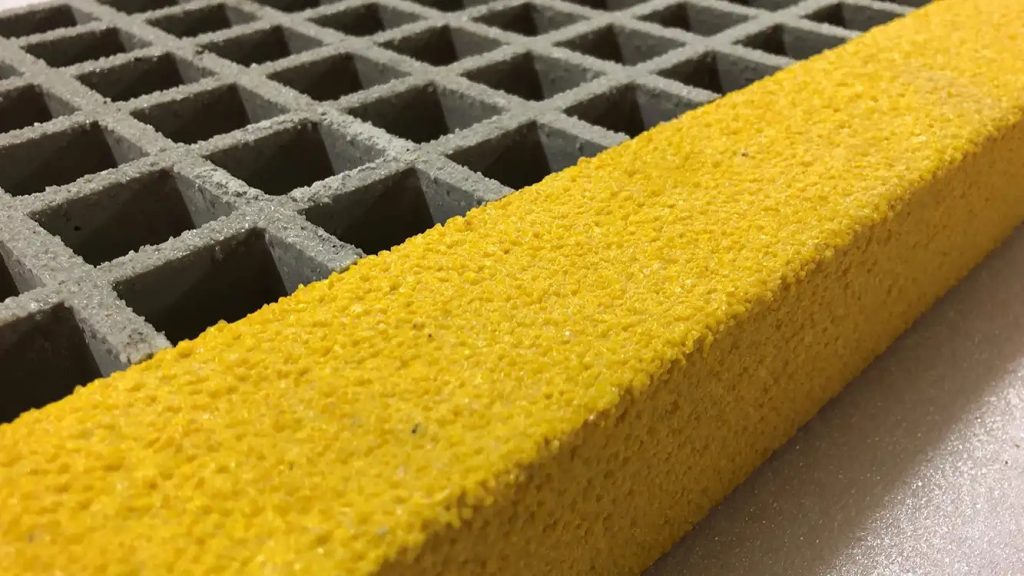

GRP Grating (Glass Reinforced Plastic Grating) is a composite material made of fiberglass and resin. The combination results in a high-strength, lightweight, and corrosion-resistant product ideal for aggressive and demanding environments.

Its structure typically comes in two main forms: molded and pultruded. Both types offer unique benefits, ensuring GRP Grating can be tailored to different applications depending on strength, load requirements, and environmental conditions.

Why GRP Grating Is Becoming an Industry Standard

Across industrial and commercial environments, the demand for materials that offer durability, safety, and minimal maintenance has increased dramatically. GRP Grating meets all these needs while providing additional advantages that traditional metal or wooden gratings fail to deliver.

The shift toward using GRP Grating is largely due to its ability to withstand harsh weather, chemicals, and heavy loads without deteriorating. For companies looking to improve efficiency and reduce long-term operational costs, this material provides an excellent investment.

Major Benefits of Using GRP Grating

1. Exceptional Corrosion Resistance

One of the most significant advantages of GRP Grating is its outstanding resistance to corrosion. Unlike steel, which rusts when exposed to moisture, or wood, which rots over time, GRP materials remain unaffected by saltwater, chemicals, and extreme pH conditions.

Why This Matters

- Ideal for marine environments

- Perfect for chemical plants

- Reduces replacement and maintenance costs

Industries that operate in wet or corrosive environments particularly benefit from GRP Grating, as it retains structural integrity and appearance for many years.

2. High Strength-to-Weight Ratio

Despite being lightweight, GRP Grating offers impressive strength. It can withstand heavy loads and high impacts without bending or breaking. The fiberglass reinforcement provides exceptional rigidity, making it suitable for heavy-duty industrial applications.

Advantages of Lightweight Construction

- Easier transportation

- Simple and fast installation

- Lower structural support requirements

This combination of strength and low weight makes GRP Grating superior to steel grating in many modern engineering scenarios.

3. Enhanced Safety Features

Safety is a top priority in industrial and commercial environments, and GRP Grating delivers multiple built-in safety benefits.

Slip Resistance

The gritted top surface provides excellent slip resistance, even when wet or oily. This dramatically reduces the risk of workplace accidents.

Fire Retardancy

Most types of GRP Grating are manufactured with fire-retardant resins, making them compliant with strict safety standards.

Electric & Thermal Insulation

Since GRP is non-conductive, it provides additional protection in electrical environments and reduces heat transfer, unlike metal gratings.

These features collectively make GRP Grating one of the safest materials for elevated walkways, platforms, stair treads, and work areas.

4. Long Lifespan and Durability

Longevity is one of the most attractive aspects of GRP Grating. Designed to withstand harsh conditions, it exhibits an impressive lifespan with minimal maintenance.

Durability Characteristics

- High impact resistance

- UV stability

- Minimal wear and tear

- Resistance to biological growth like mold or algae

Because GRP Grating maintains its shape and structural capabilities for decades, it significantly reduces long-term costs, making it a smart investment for projects of all scales.

5. Cost-Effective Over Time

While GRP Grating may have a slightly higher upfront cost compared to traditional steel or wooden alternatives, the long-term financial benefits far outweigh the initial investment.

Cost-Saving Factors

- Zero corrosion management

- Reduced installation costs due to lightweight design

- No painting or surface treatments required

- Less frequent replacements

Many industries report substantial savings over 5–10 years when replacing steel platforms with GRP Grating.

6. Easy Installation and Customization

Installation time can significantly affect project budgets, and GRP Grating excels in this area. Its lightweight structure allows workers to handle and position the panels without heavy lifting equipment.

Customization Advantages

- Can be cut on-site without special tools

- Fits complex layouts

- Available in various thicknesses, colors, and mesh patterns

Because GRP Grating can be easily shaped and modified, it provides project flexibility that metal grating cannot match.

7. Aesthetic Appeal and Design Flexibility

Modern industrial and commercial spaces value both function and appearance. GRP Grating offers a sleek, professional look and comes in a wide range of colors.

Aesthetic Advantages

- Colorfast pigments

- Uniform surface finish

- Blends well with architectural designs

This makes GRP Grating suitable not only for industrial platforms but also for commercial walkways, public spaces, and recreational facilities.

8. Eco-Friendly Solution

Sustainability is increasingly important in construction and engineering. GRP Grating supports eco-friendly initiatives because:

- It has a long lifespan, reducing material waste

- It requires less maintenance and fewer chemical treatments

- Its lightweight nature reduces energy consumption during transportation

This makes GRP Grating a greener choice compared to traditional alternatives.

Common Industrial and Commercial Applications of GRP Grating

Industrial Applications

- Offshore oil platforms

- Chemical processing plants

- Water treatment facilities

- Power stations

- Manufacturing plants

In these environments, GRP Grating is used for walkways, platforms, trench covers, stair treads, and maintenance areas.

Commercial Applications

- Public walkways

- Rooftop access platforms

- Swimming pool areas

- Car parks

- Architectural features

The slip-resistant and corrosion-resistant properties of GRP Grating make it ideal for both functional and aesthetic applications.

Comparing GRP Grating With Traditional Materials

GRP Grating vs. Steel Grating

- GRP does not corrode

- GRP is non-conductive

- Steel is heavier and harder to install

- GRP requires no painting or coating

GRP Grating vs. Wooden Grating

- Wood rots, warps, and absorbs moisture

- GRP requires no chemical treatments

- GRP lasts significantly longer

Across every comparison, GRP Grating consistently emerges as the superior option due to its durability, safety, and low maintenance demands.

How GRP Grating Enhances Project Performance

Implementing GRP Grating in industrial and commercial projects improves overall operational efficiency. Its ability to provide long-term reliability without constant upkeep allows companies to allocate resources more effectively.

Additionally, the safety benefits contribute to fewer workplace accidents, ensuring a safer working environment and reducing liability risks.

Businesses focusing on long-term sustainability, cost savings, and enhanced safety can achieve significant improvements by switching to GRP Grating.

Why Choose GRP Grating for Your Next Project

Whether you are designing a new facility or upgrading an existing one, GRP Grating offers unmatched value. Its versatility allows it to meet the demands of even the toughest industrial environments while maintaining visual appeal for commercial installations.

From corrosion resistance to long-term durability and cost savings, the advantages of GRP Grating make it a smart and future-proof choice.

Conclusion

GRP Grating has become an essential material for modern industrial and commercial projects due to its strength, safety features, corrosion resistance, and long-term cost efficiency. It outperforms traditional materials in nearly every category, offering a reliable and adaptable solution for harsh or high-traffic environments.

With its lightweight construction, easy installation, environmental benefits, and impressive durability, GRP Grating continues to set new standards in engineering and construction. If your project requires a versatile, long-lasting, and safe platform or walkway solution, GRP Grating stands as the ideal choice.