Understanding Custom Hydraulic Equipment

What Is Custom Hydraulic Equipment?

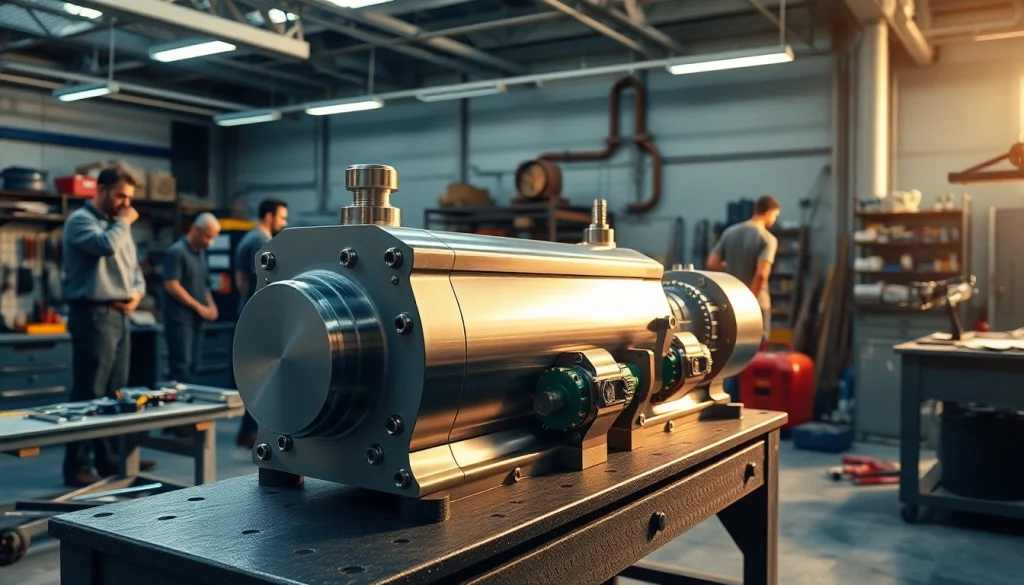

Custom hydraulic equipment refers to hydraulic systems and components designed specifically to meet the unique requirements of businesses or applications. These systems can include hydraulic pumps, cylinders, valves, and other essential components that are tailored to fit the operational needs of various industries. Unlike off-the-shelf solutions, custom hydraulic equipment is often engineered to provide enhanced performance, durability, and efficiency. The design process typically involves a deep understanding of the intended application, as well as collaboration between engineers and the end-users to optimize functionality.

Benefits of Custom Hydraulic Equipment

The development of custom hydraulic equipment brings numerous advantages that can significantly enhance operational efficiency:

- Tailored Solutions: Custom designs ensure that the equipment fits perfectly within the existing systems and meets specific performance criteria.

- Increased Efficiency: Optimally designed hydraulic systems can lead to better energy use and fewer operational bottlenecks.

- Durability and Reliability: High-quality materials and precise engineering result in more reliable equipment that stands the test of time.

- Cost-Effectiveness: Reducing downtime and maintenance costs through highly efficient designs often results in overall cost savings.

- Innovation: Companies frequently push the boundaries of technology with custom solutions that integrate the latest advancements in hydraulic technology.

Applications Across Industries

Custom hydraulic equipment finds applications in a multitude of industries including:

- Construction: Hydraulic systems are pivotal in heavy machinery, such as excavators, bulldozers, and cranes.

- Aerospace: Precision in hydraulics is crucial for aircraft systems, impacting everything from landing gear to flight controls.

- Manufacturing: Tailored hydraulic machinery increases productivity in manufacturing processes by enabling automated tasks.

- Marine: Custom hydraulic solutions are essential in managing the operational needs of marine vessels, particularly for equipment like winches and stabilizers.

- Oil and Gas: Customized hydraulic tools are used in drilling and production operations, where specific performance demands are crucial.

Designing Your Custom Hydraulic Equipment

Key Design Considerations

The design process for custom hydraulic equipment encompasses multiple key considerations to ensure optimal function:

- Load Requirements: Assessing the maximum loads the equipment will handle is essential for determining component specifications.

- Operating Environment: Designing for the intended environment, including temperature, moisture, and exposure to corrosive substances, is key to durability.

- Integration: Ensuring the custom hydraulic equipment seamlessly integrates with existing systems and processes is paramount.

- Regulatory Compliance: All designs must adhere to industry regulations and standards for safety and performance.

Material Selection for Durability

The materials chosen for custom hydraulic equipment directly influence its performance and longevity. Common materials include:

- Steel: Known for its strength and durability, steel is often used for hydraulic cylinders and structural components.

- Aluminum: Lightweight and resistant to corrosion, aluminum is ideal for applications where weight savings are crucial.

- Composite Materials: Offering enhanced strength-to-weight ratios, composite materials are becoming increasingly popular.

- Seals and O-rings: Selecting appropriate materials for seals ensures a leak-free operation, which is vital for system performance.

Customization Options for Optimal Performance

To achieve optimal performance, custom hydraulic systems can include various options:

- Variable Displacement Pumps: Allow for better control of flow rates according to operational needs.

- Customized Valves: Tailored valves can provide precision control and enhanced safety features.

- Integrated Sensors: Incorporating sensors into hydraulic systems enables real-time monitoring and maintenance alerts.

- Enhanced Control Systems: Leveraging advanced control technologies can optimize system performance and reduce energy consumption.

Manufacturing Process of Custom Hydraulic Equipment

Steps in the Manufacturing Process

The manufacturing of custom hydraulic equipment typically follows a structured process to ensure quality and performance:

- Design Verification: Engineering teams collaborate to refine designs and ensure they meet the specified requirements.

- Prototyping: Creating prototypes allows for testing and validation before full-scale production.

- Material Procurement: Quality materials are sourced from reliable vendors to ensure consistency and reliability.

- Production: Equipment is manufactured using precision machinery to maintain high quality.

- Testing: Each unit undergoes rigorous testing to confirm its performance and reliability before being delivered.

Quality Control Measures

Quality control is a vital part of the manufacturing process to ensure product reliability:

- Regular Inspections: Throughout the production process, regular inspections are conducted to identify any defects early.

- Performance Testing: Hydraulic systems are tested under conditions that mimic real-world applications to ensure they perform as expected.

- Documentation: Maintaining thorough documentation of all tests and inspections helps track quality performance over time.

Reducing Lead Time in Production

Reducing lead times in the production of custom hydraulic equipment is crucial for meeting customer demands:

- Streamlining Processes: Analyzing and optimizing production workflows can identify bottlenecks and reduce delays.

- Inventory Management: Maintaining a well-managed inventory of essential components can speed up the assembly process.

- Collaboration with Suppliers: Building strong partnerships with suppliers can improve material delivery times and reliability.

Installation and Maintenance

Guidelines for Installation of Custom Hydraulic Equipment

The installation of custom hydraulic equipment should be approached with care to ensure optimal functionality:

- Site Preparation: Ensure that the installation site meets required specifications, including structural integrity and safety protocols.

- Clearance and Accessibility: Ensure adequate space around the equipment for operation, maintenance, and emergency access.

- System Checks: Complete thorough system checks to identify any potential failures before operation.

Routine Maintenance Best Practices

To maximize the lifespan and efficiency of custom hydraulic equipment, routine maintenance is essential:

- Regular Fluid Checks: Monitor hydraulic fluid levels regularly, and change the fluid according to manufacturer guidelines.

- Inspect for Leaks: Regularly inspect all connections and seals for signs of leaks or wear.

- Component Maintenance: Schedule routine checks on components such as filters, hydraulic cylinders, and hoses to prevent breakdowns.

Common Issues and Troubleshooting

Understanding common equipment issues can enhance troubleshooting efforts:

- Insufficient Power: Often caused by air in the system or improper fluid levels—check for leaks and prime the system.

- Unresponsive Controls: Typically the result of valve failure or obstructions—ensure all controls are clear and functioning properly.

- Overheating: Can indicate inadequate cooling or fluid circulation—check for blockages and ensure fluid is at appropriate levels.

Future Trends in Custom Hydraulic Equipment

Innovation in Hydraulic Technology

Hydraulic technology continues to advance, bringing innovative solutions for custom hydraulic equipment:

- Smart Hydraulics: The integration of IoT technologies allows for real-time monitoring of system performance, helping to reduce downtime.

- Advanced Materials: Ongoing research into durable, lightweight materials enhances efficiency and reduces energy consumption.

Impact of Automation

The incorporation of automation into hydraulic systems is transforming how industries operate:

- Efficiency Improvements: Automated systems reduce human error and can operate continuously, leading to increased productivity.

- Data Analysis: Automating data collection and analysis offers insights that can inform maintenance and operational improvements.

Sustainability in Hydraulic Solutions

Sustainability is becoming a crucial consideration for hydraulic solutions:

- Energy Efficiency: Developing hydraulic systems that consume less energy helps reduce overall environmental impact.

- Recyclable Materials: Using sustainable materials in production processes facilitates responsible disposal and reduces waste.

Frequently Asked Questions

What are the advantages of custom hydraulic equipment?

Custom hydraulic equipment offers tailored solutions for specific applications, increased efficiency, and enhanced durability, leading to cost savings over time.

How do I choose the right materials for hydraulic equipment?

Consider factors such as strength, weight, corrosion resistance, and compatibility with hydraulic fluids to select the best materials for your application.

What maintenance practices should I follow?

Routine checks of fluid levels, inspecting for leaks, and maintaining components like filters and hoses are essential for optimal equipment performance.

How is custom hydraulic equipment manufactured?

The process involves design verification, prototyping, material procurement, production, and rigorous testing to ensure quality and performance.

What are emerging trends in hydraulic technology?

Key trends include the integration of IoT for smart hydraulics, automation for efficiency improvements, and a focus on sustainability in materials and practices.